- info@eltech.in

- +91-96196 86917, +91-84509 80333

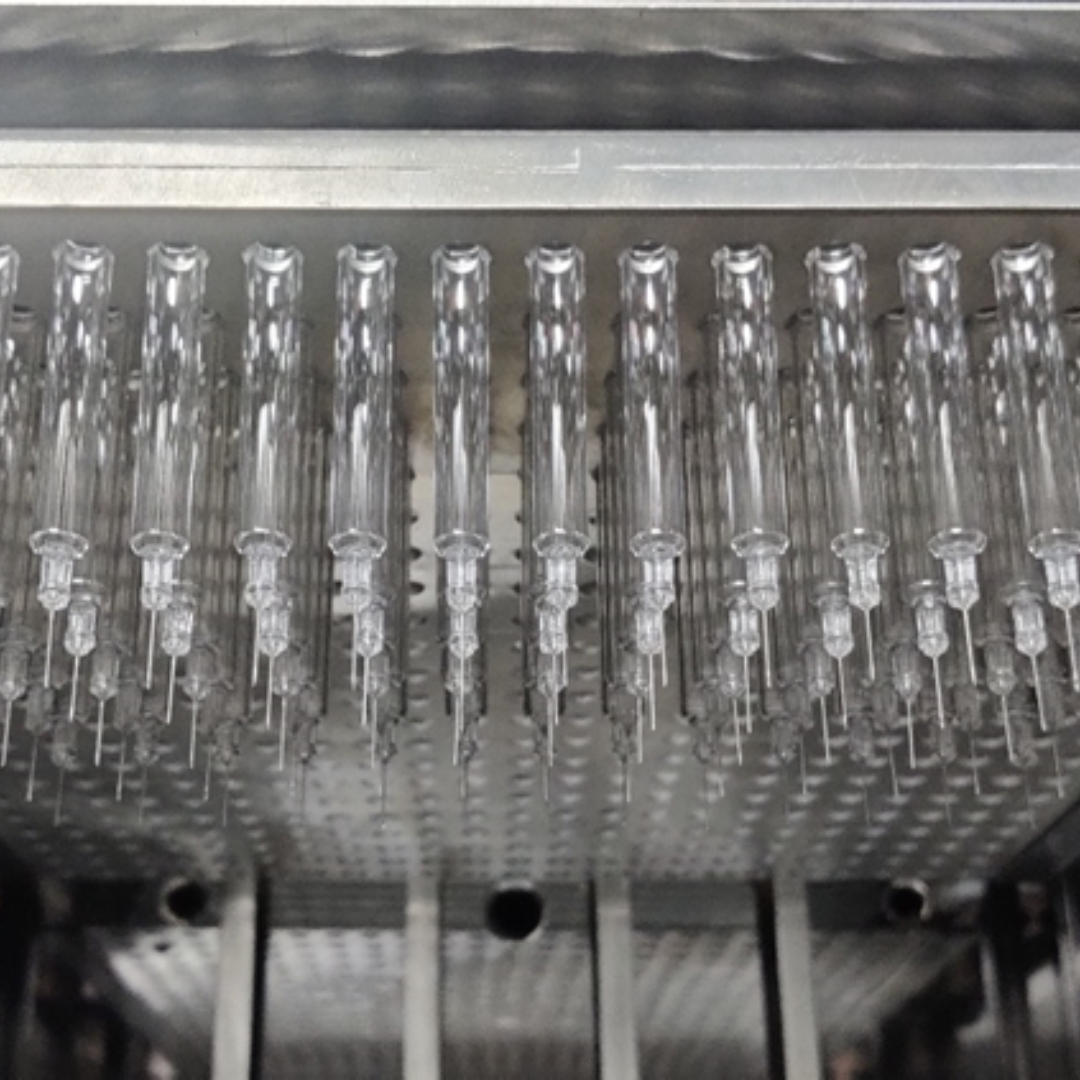

The surface of the syringe has been modified via vacuum plasma treatment, which can enhance how well the solution flows inside of it. The plasma treatment can increase flow rate, reduce dead volumes, and improve solution mixing efficiency by generating a certain surface roughness.

Making any polymer's inner surface hydrophilic such that it tends to increase surface energy, such as polycarbonate (PC), polypropylene (PP), or any other polymer. T he silicone oil is sprayed on the inner surface of the syringe, after the inner wall/surface is modified to make it hydrophilic, which tends to evenly and thoroughly spread the silicone oil on the inside of the syringe barrel wall. Not only is the silicone oil evenly spread but thanks to the plasma, the initial force and the glide force between the plunger and the inside surface of the syringe barrel are also decreased. In consequence, this can lessen the possibility of the plunger sticking or jamming while in use and tends to help in a smooth easy flow of the drug filled inside the barrel.

Vacuum plasma therapy can also clean and disinfect the syringe surface, improving its suitability for usage in medical settings. In addition to lowering the likelihood of negative responses or infections, this procedure can make the syringe surface more biocompatible.