- info@eltech.in

- +91-96196 86917, +91-84509 80333

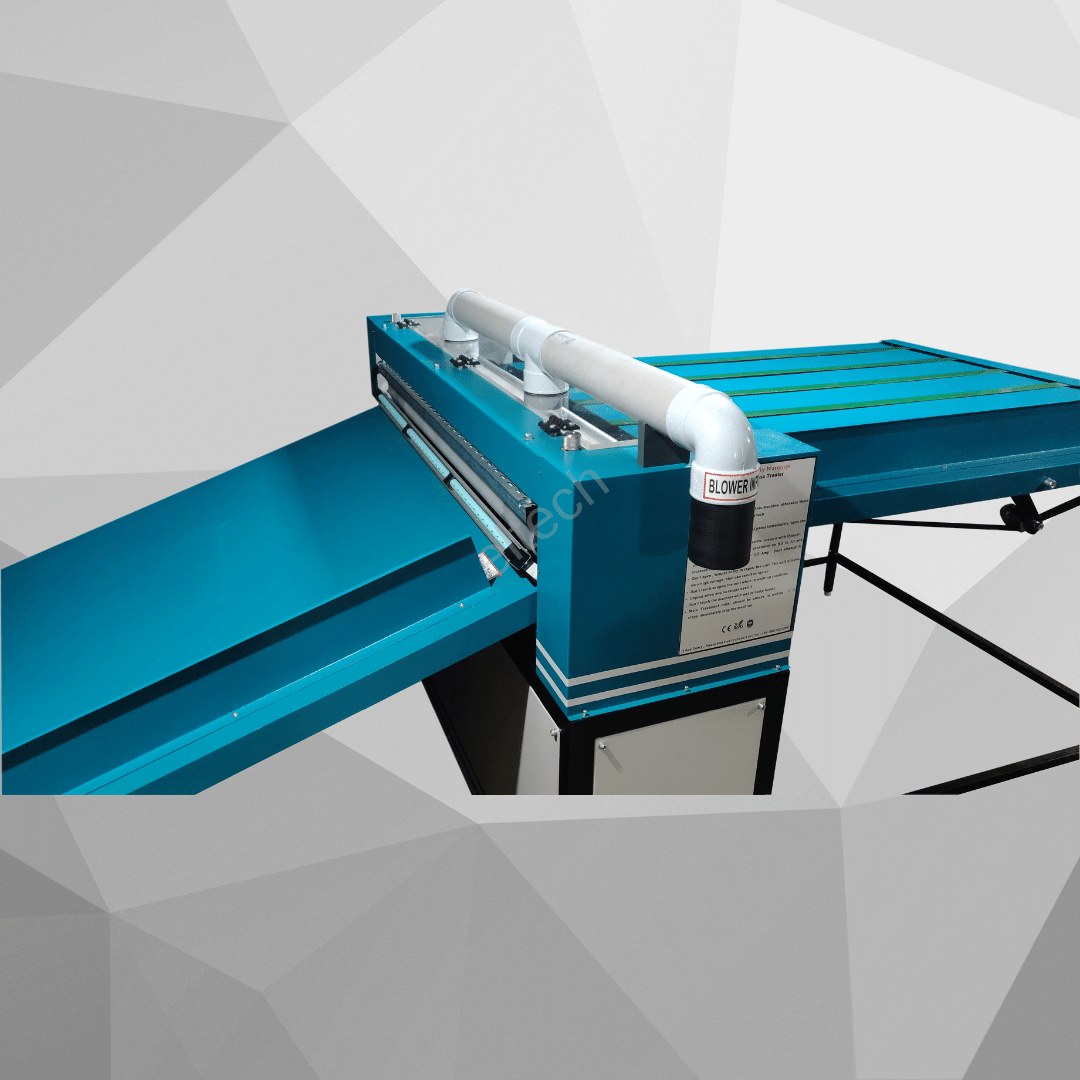

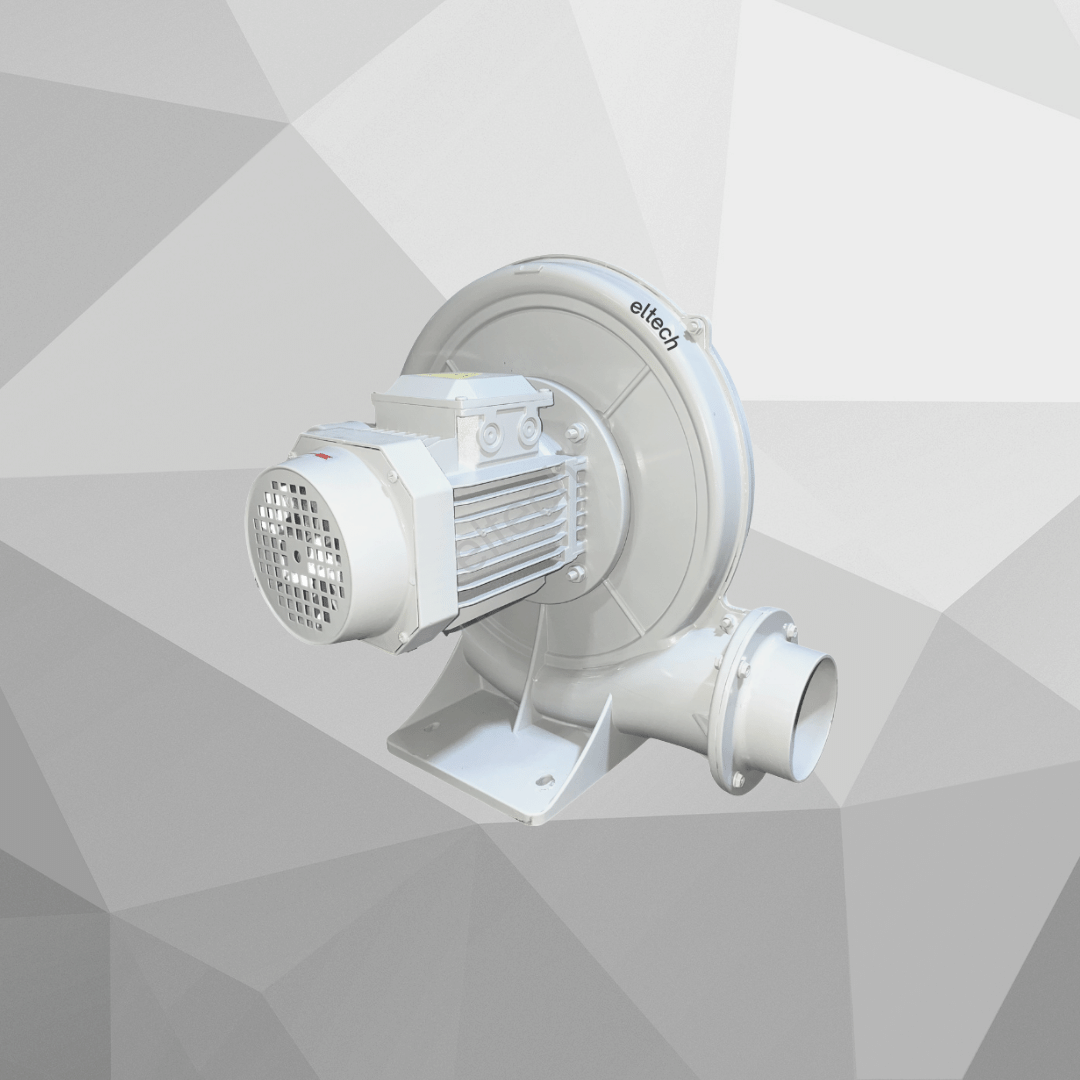

LABORATORY TYPE CORONA TREATMENT TO TREAT LABELS FOR TESTING PURPOSE IN LABORATORY

A sheet Corona treater is a device used in the printing industry to improve the adhesion of inks and coatings to plastic sheets. The process of Corona treatment involves passing the plastic sheets through a corona discharge, which modifies the surface of the plastic to increase its surface energy and improve adhesion.

Eltech sheet corona treater is widely used to treat PP, PVC and metallised polyester laminated sheets to increase surface tension and gives better printing and adhesion. Water-based and UV inks printed on plastic films and other substrates create a need for the substrate to be treated prior to printing.

Conventional method of roll to roll treatment is standard practice, but in Offset, Sheet corona treatment is required to increase surface tension or improve the printability. Some substrates are corona-treated when they are manufactured. Many of these substrates require a surface energy boost to match a particular ink or coating. This is done with corona pretreaters on the press just prior to the coating application point.

PVC, PP, LD, Foam, Flex, metallized polyester, PE, OPP and other high-low density plastic materials should particularly be Corona treated to enhance the quality of the final product.