- info@eltech.in

- +91-96196 86917, +91-84509 80333

Plasma surface treatment is a widely used technique in the automotive industry for improving the adhesion of coatings ...

Click here to know more

Plasma surface treatment is a widely used process in the lithium-ion battery industry for modi ...

Click here to know more

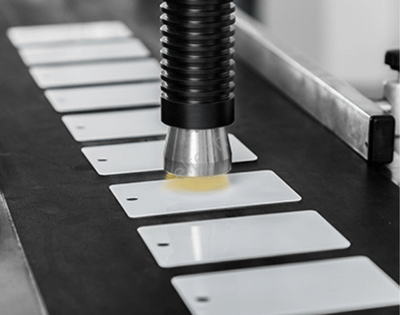

Plasma surface treatment can also be used to improve the surface properties of plastic credit car...

Click here to know more

Plasma surface treatment on bottles is a process that is used to modify the surface properties of the bottles, such a...

Click here to know more

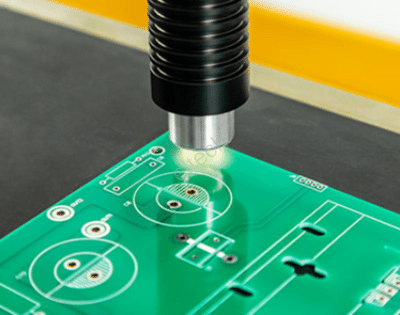

Plasma surface treatment is a commonly used process in the printed circuit board (PCB) industry. It involves us...

Click here to know more

Plasma surface treatment can be beneficial for improving the adhesion and reliability of LED lead fra...

Click here to know more

Plasma treatment is widely used in the optics industry for various purposes such as cleaning, activa...

Click here to know more

Plasma surface treatment is an important technique in the electronics industry for improving the adhesion of thin fil...

Click here to know more

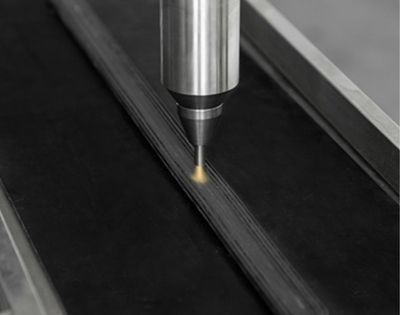

Plasma surface treatment can be used to modify the surface properties of wires before inkjet printing. Inkjet printing ...

Click here to know more

Plasma treatment is a commonly used surface modification technique that can enhance the surface proper ...

Click here to know more

Plasma surface treatment is a widely used process in the medical manufacturing industry. It involves using a plas...

Click here to know more

Plasma surface treatment is commonly used to modify the surface properties of plastics. Plastics are widely us...

Click here to know more

Plasma surface treatment is a technique that can be used on rubber materials to modify their surface prop...

Click here to know more

Plasma surface treatment is a technique used in inkjet printing to improve the adhesion of ink to a substrate. Inkjet prin...

Click here to know more

Plasma surface treatment is a technique used to modify the surface properties of glass. Glass is a widely used material in ma...

Click here to know more

Plasma surface treatment is a common process in the packaging industry that involves using a plasma sour...

Click here to know more

Plasma surface treatment can be used to improve the adhesion of glue and other adhesives in fol...

Click here to know more