- info@eltech.in

- +91-98672 22298

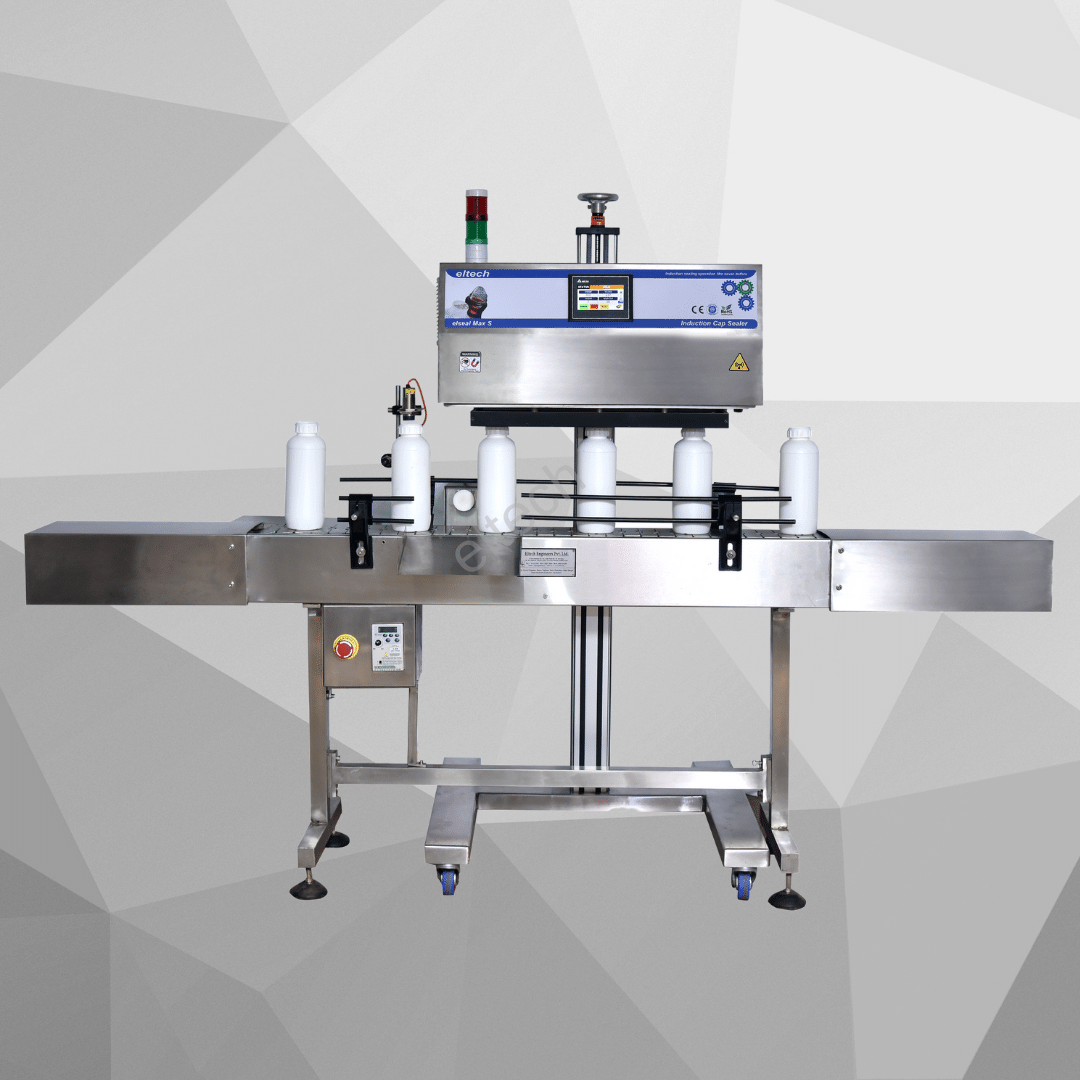

A Fully Automatic Induction Cap Sealer is a machine used in the packaging industry to seal caps onto bottles, jars, or other containers using induction sealing technology. The induction sealing process involves applying a cap with an aluminum foil liner to the container, and then using an electromagnetic field to heat and seal the liner onto the container.

The Fully Automatic Induction Cap Sealer is designed to handle a high volume of containers, with the sealing process automated for efficiency and consistency. The machine typically consists of a conveyor system that moves the containers through the sealing process, with the sealing head applying the electromagnetic field and pressure to seal the liner onto the container.

Fully Automatic Induction Cap Sealer is the latest of a concept developed by Eltech's powerful engineering team. Eltech offers compact air cool on line automatic cap sealing systems for high speed cap sealing applications. Eltech has been upgrading its technology of sealing with best features for revolutionary technology. It is a tremendous achievement for our development team and a great breakthrough for the industry. New performance helps to achieve better sealing standards. With an advanced touch screen operating system it has been value for the product. It helps sealing operation like never before.

Overall, the Fully Automatic Induction Cap Sealer is a valuable tool for the packaging industry, offering high-speed operation, consistent sealing quality, versatility, and improved product integrity. It is a cost-effective and efficient solution for sealing caps onto bottles, jars, or other�containers.