- info@eltech.in

- +91-96196 86917, +91-84509 80333

LABORATORY TYPE CORONA TREATMENT TO TREAT LABELS FOR TESTING PURPOSE IN LABORATORY

Corona treating is a very effective way to increase the surface tension of virtually any material. When properly applied to your substrate, corona treating produces the higher surface dyne levels needed for good adhesion even on the more difficult-to-treat materials like polypropylene and polyethylene.

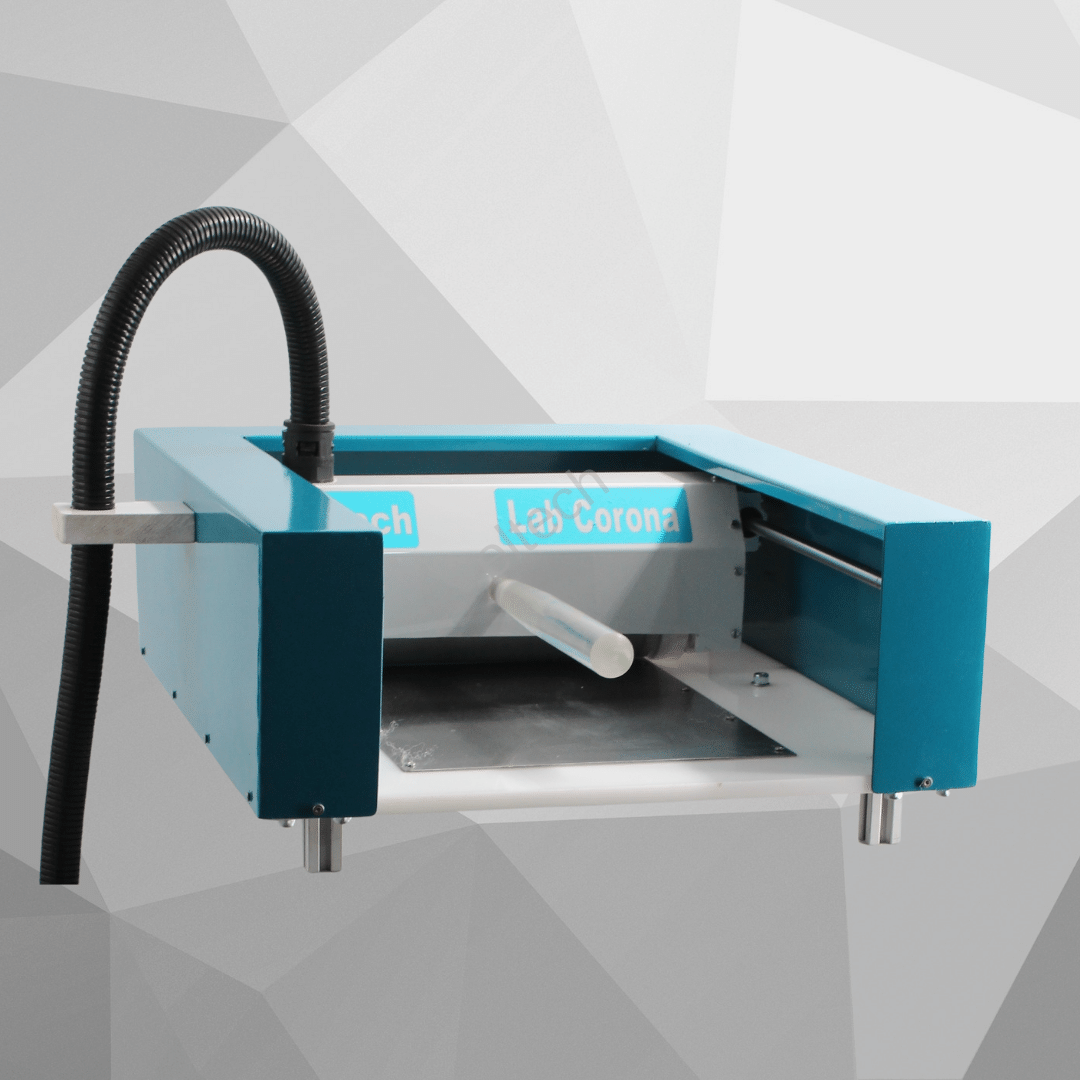

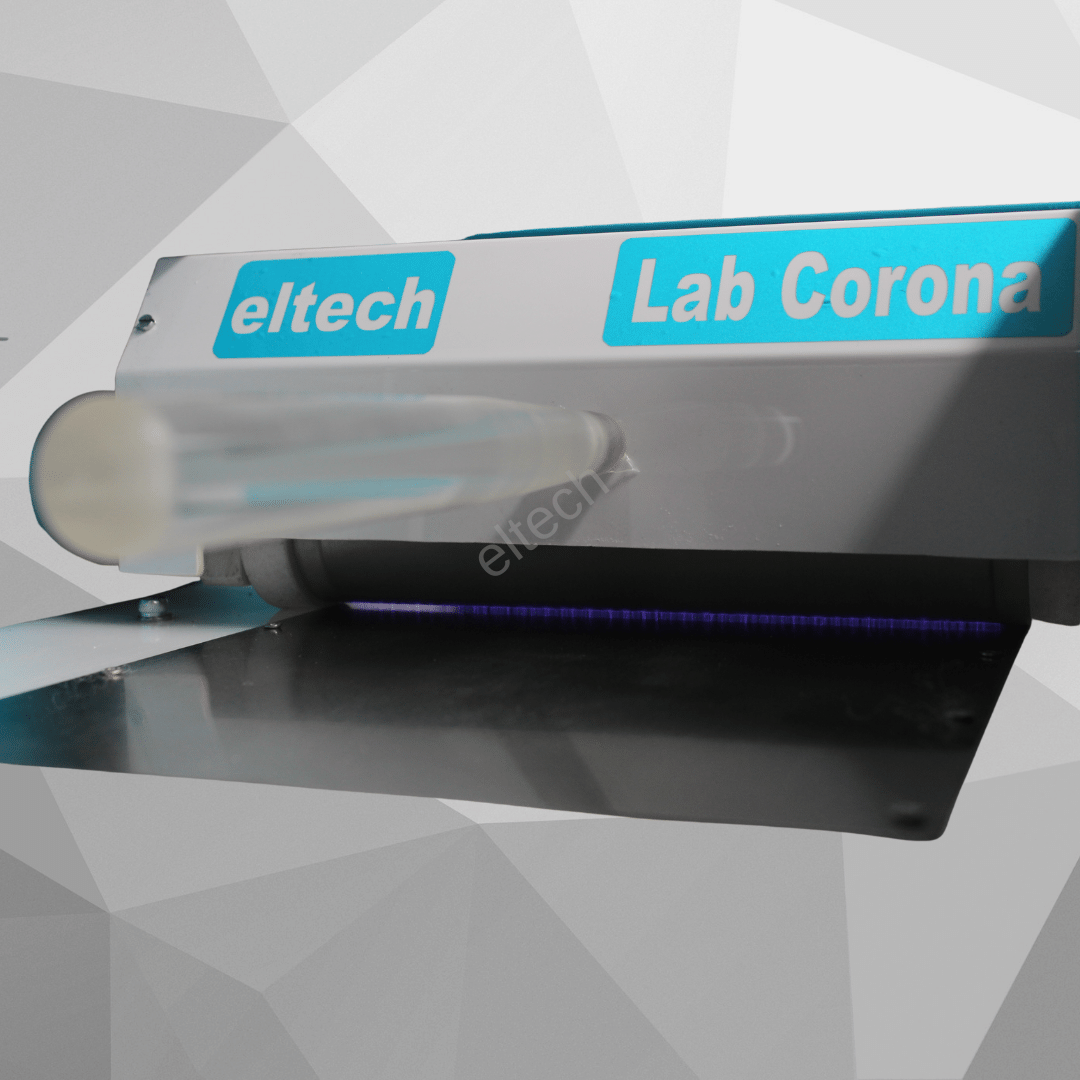

Other common corona treating applications include nylon, vinyl, PVC, PET, metallized surfaces, foils, paper, paperboard stock, and other materials. For the treatment of sample film prior to adhesion or printing. The film to be tested is placed on the earthed base plate and is then passed over with the manual roller electrode.

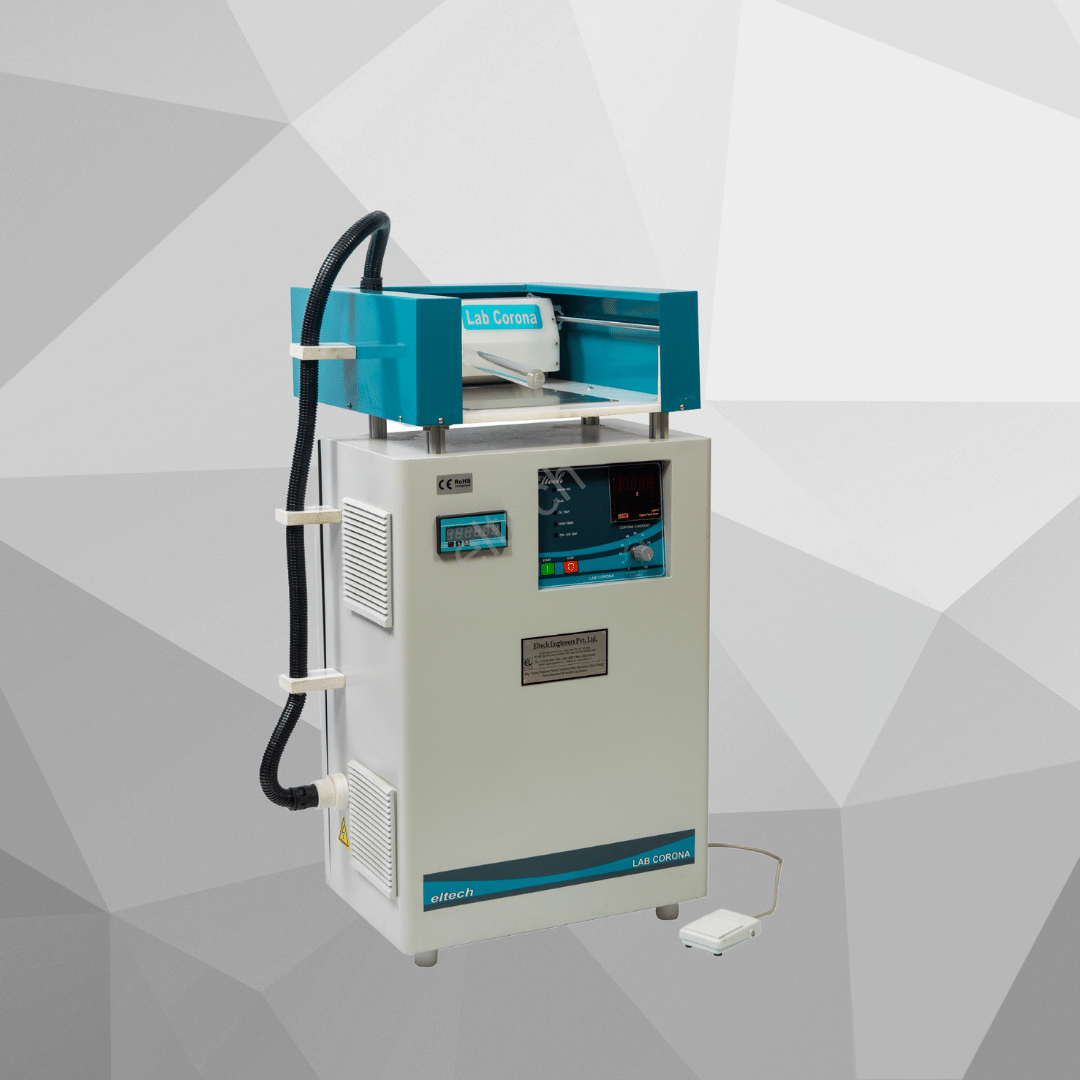

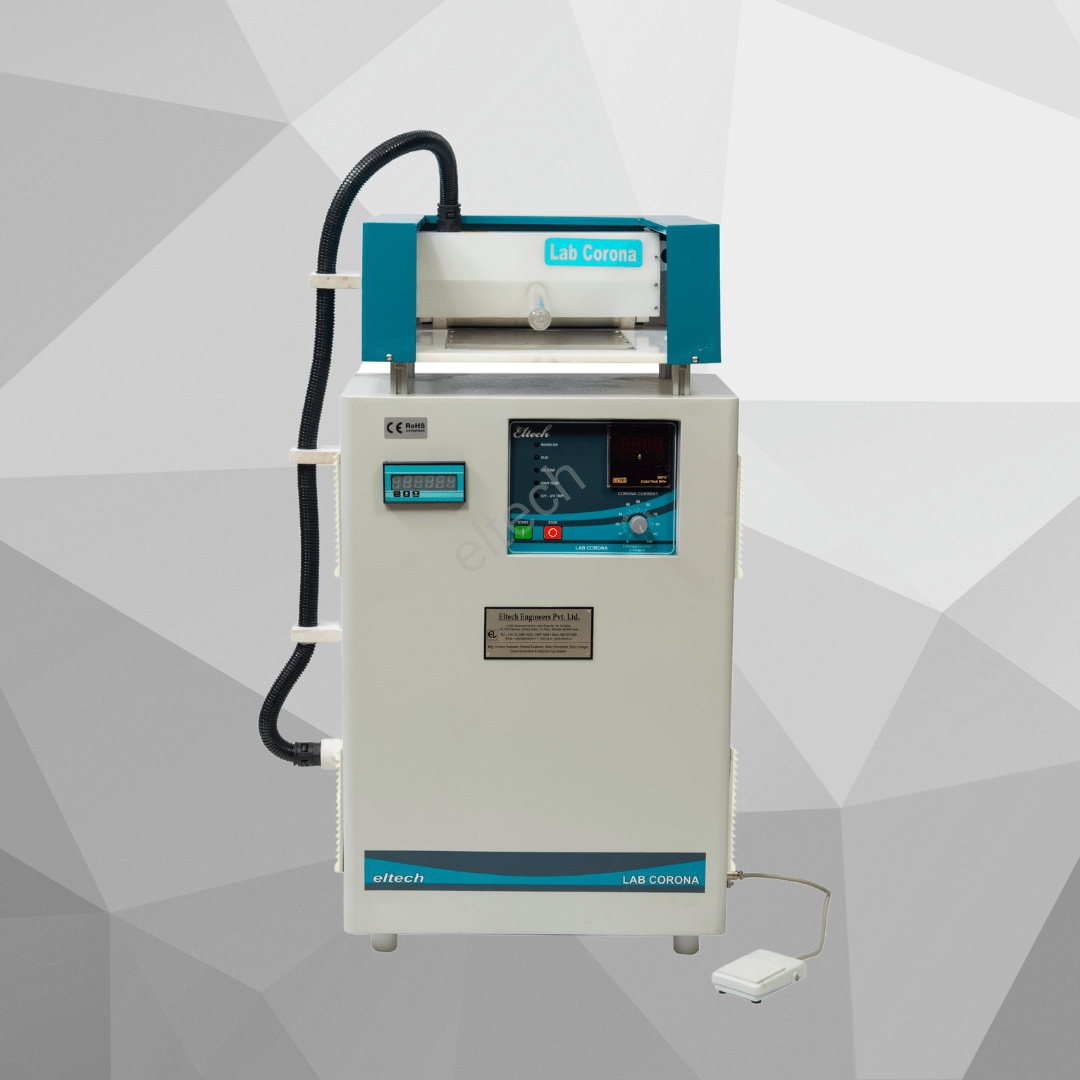

generator power can be set and is displayed. The intensity can also be regulated by varying the movement speed.

The unit is most suitable for quick and simple tests. The compact design of the unit allows it to be taken to a customer and to perform tests on site.

The device comprises a semi-conductor generator with an integrated transformer for high-voltage generation, the hand roll electrode (standard working width 200mm), the earthed ground plate power cable and a hand or foot-operated switch for the activation of the Corona discharge. The output (intensity of the Corona discharge) can be adjusted at a potentiometer and read off a display.

The purpose of corona treatment is to optimise the adhesion properties on polymer-based materials. The low surface energy of polymer-based substrates often leads to poor adhesion of inks, glues and coatings which by nature present significantly high surface energies. To obtain optimum adhesion, it is crucial that the surface energy of the substrate is equal or higher than the surface energy of the material to be applied to the polymer.