- info@eltech.in

- +91-96196 86917, +91-84509 80333

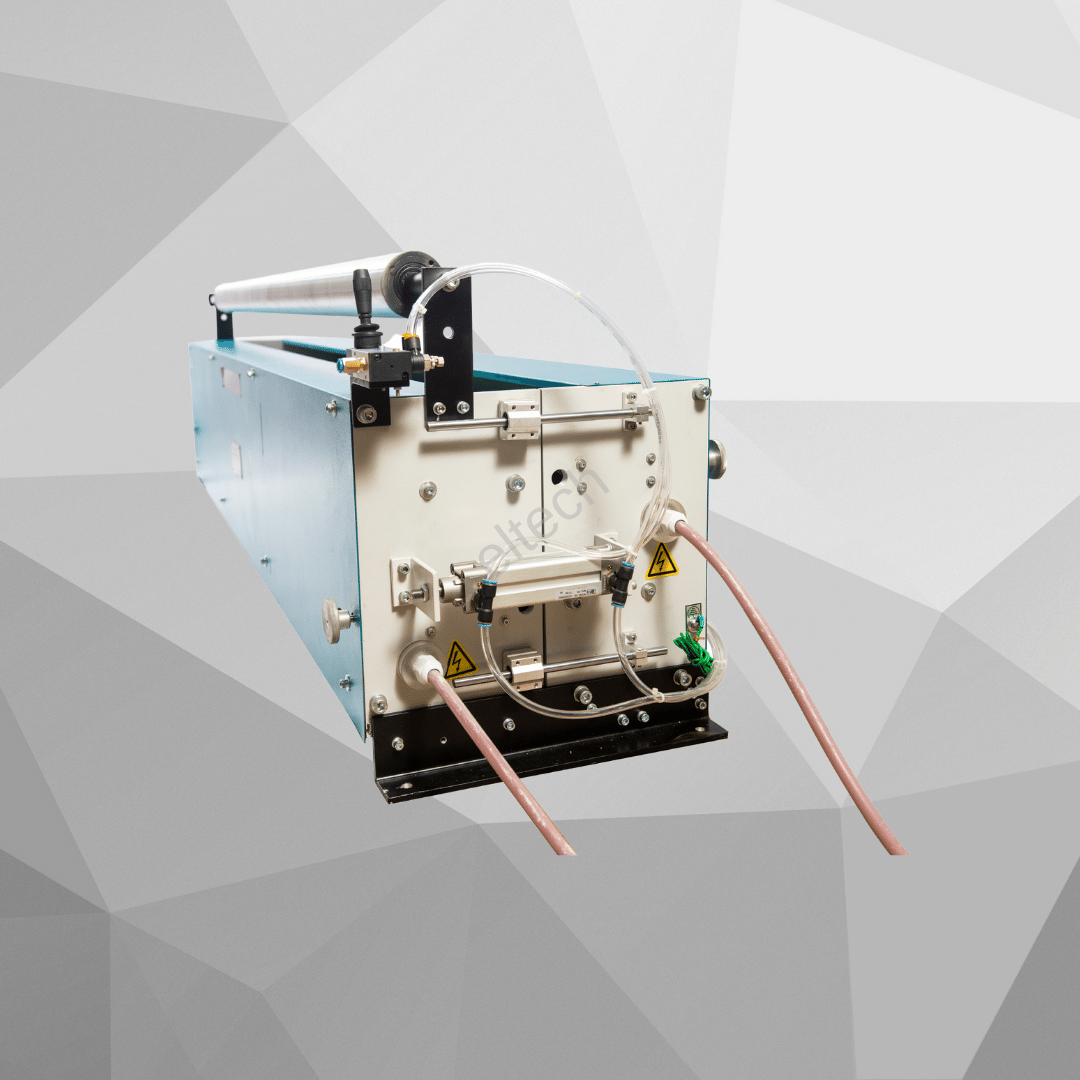

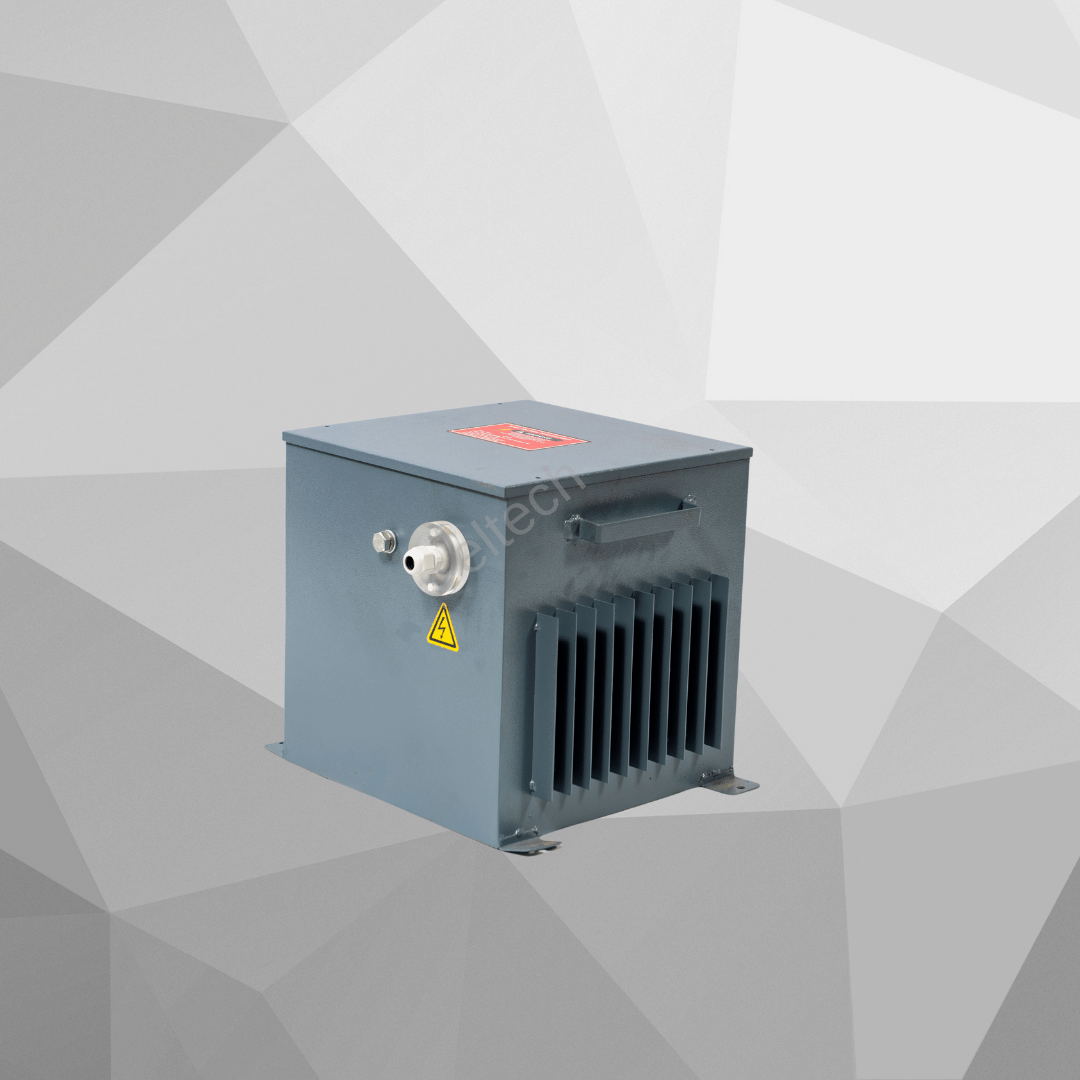

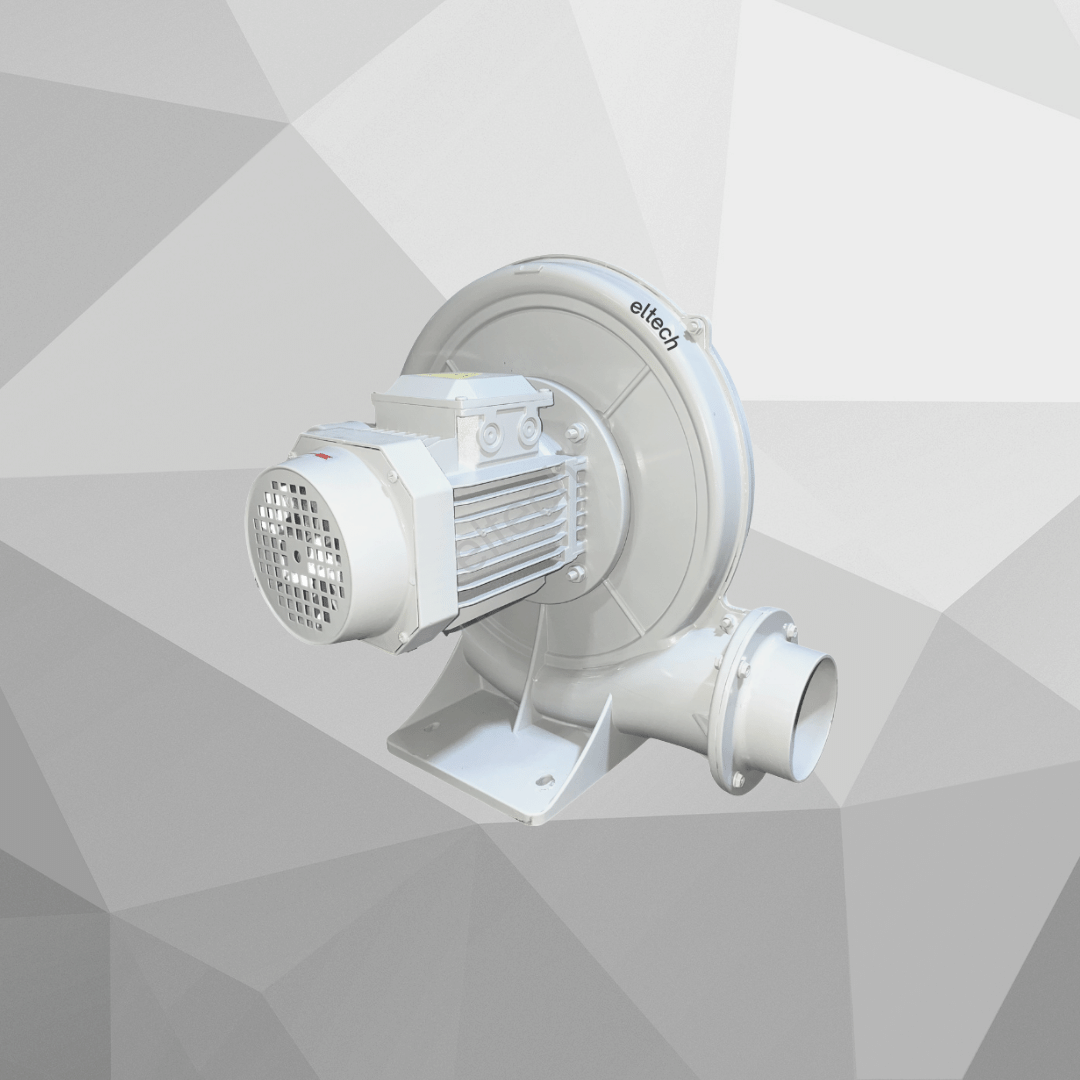

Corona treatment system is a very effective way to increase the surface tension of virtually any material. Surface treatment is required for plastic films/fabrics whose normal surface tension is not sufficiently high to permit good wetting by flexo graphic inks.

In a multilayer film plant, a Corona Treater is used to enhance the adhesion of coatings or inks to multiple layers of films. Unlike a monolayer film plant, where the Corona Treater is used to treat a single layer of film, the Corona Treater for a multilayer film plant must be able to treat multiple layers simultaneously.

The Corona Treater used in a multilayer film plant works by generating a corona discharge that ionizes the air between the electrode and the film. This ionized air reacts with the film's surface, creating polar groups on the surface of each layer of the film. The polar groups increase the wettability of the film and improve the adhesion of coatings or inks to each layer of the film.

When selecting a Corona Treater for a multilayer film plant, it is essential to consider the number of layers to be treated and the width and speed of the film. It is also crucial to choose a reliable and durable Corona Treater that can withstand the harsh environment of a manufacturing plant and provide consistent and repeatable treatment results. Additionally, the Corona Treater should be able to treat a range of film types, thicknesses, and surface energies, and offer flexibility in treatment settings to optimize the adhesion of coatings or inks to each layer of the film.