- info@eltech.in

- +91-96196 86917, +91-84509 80333

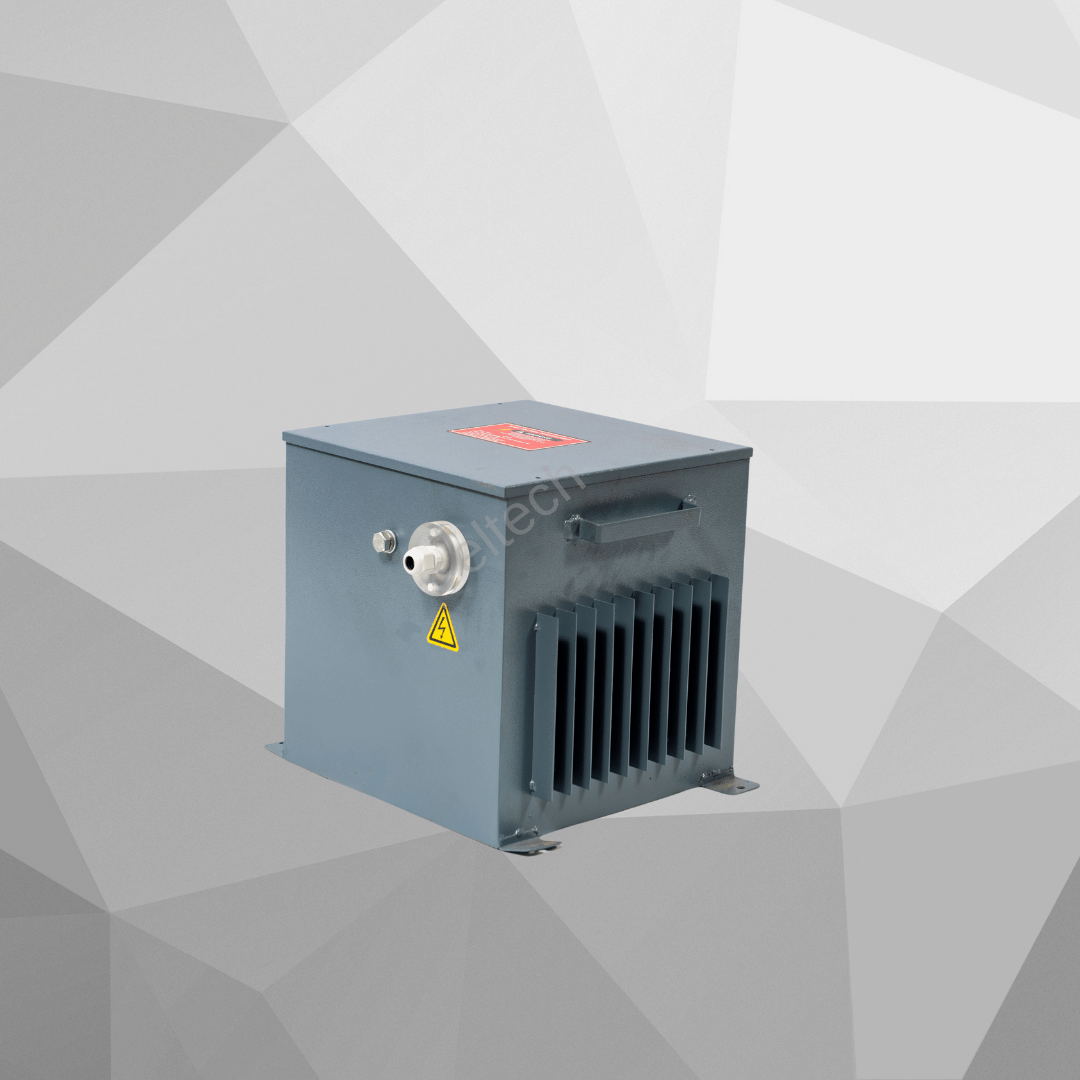

Eltech manufactures best quality corona treater for monolayer film plant extruder and this film is formed by mixing polypropylene or polyethylene(structural material) with vinyl-acetate or methacrylate(printable material). This forms the unitary mixture. Then the mixture is extruded and heated.

A Corona Treater is a device used to improve the adhesion of inks, coatings, and adhesives to plastic films. In a monolayer film plant, the Corona Treater is typically used to enhance the surface energy of the film before it is coated or printed. This treatment process creates microscopic surface irregularities, which increase the wettability of the film and improve the adhesion of subsequent coatings or inks.

The Corona Treater works by subjecting the film to a high-voltage, high-frequency electrical discharge, which ionizes the air surrounding the film. This ionized air then reacts with the film's surface, creating polar groups on the film's surface. These polar groups attract the polar molecules of coatings or inks, increasing their adhesion to the film.

When selecting a Corona Treater for a monolayer film plant, it is essential to consider factors such as the width and speed of the film, the type of film being treated, and the desired level of treatment. It is also essential to choose a reliable and durable Corona Treater that can withstand the harsh environment of a manufacturing plant and provide consistent and repeatable treatment results.