- info@eltech.in

- +91-96196 86917, +91-84509 80333

Due to the superior mechanical qualities, transparency, and biocompatibility, PDMS (polydimethylsiloxane) is a silicone-based elastomer that is frequently employed in microfluidic devices. The surface properties of PDMS can be altered by vacuum plasma treatment, which also improves the material's ability to adhere to other substances and perform better in microfluidic devices.

By adding functional groups to the surface of PDMS during vacuum plasma treatment, such as hydroxyl (-OH) and carboxyl (-COOH) groups, its wettability and adhesion to other materials can be enhanced. The PDMS surface is been cleaned and made hydrophilic by the oxygen plasma treatment by removing organic impurities and oxide coatings.

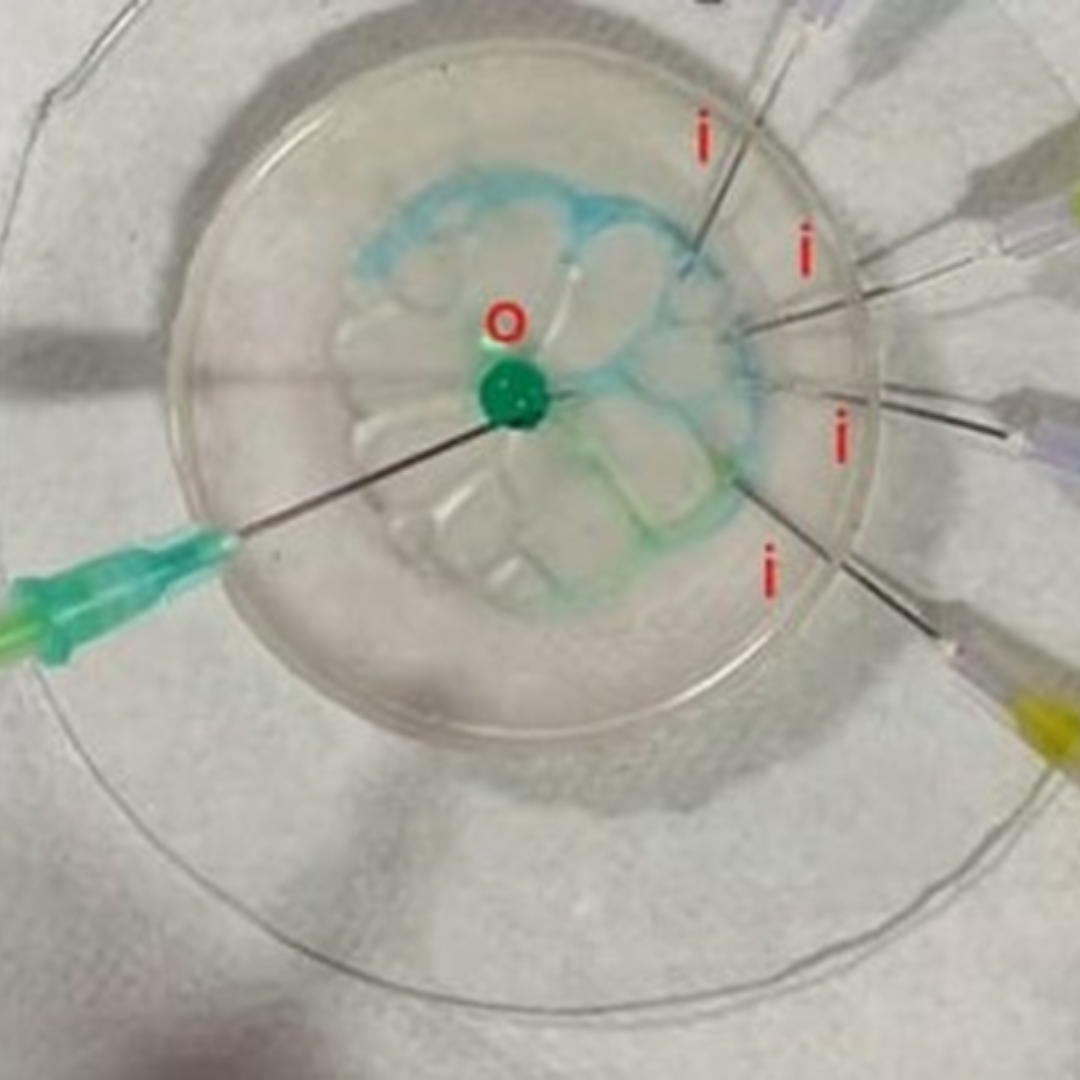

Improving the bonding of PDMS with glass or other materials is one typical use of vacuum plasma therapy for PDMS. In microfluidic devices, PDMS is frequently bonded to a glass substrate, and vacuum plasma treatment can strengthen the binding by producing reactive spots on the PDMS surface that can form covalent bonds with the glass surface.

The surface of PDMS can be patterned via vacuum plasma treatment, resulting in microstructures that can be employed for a variety of tasks, including fluid control in microfluidic devices and cell culture.