- info@eltech.in

- +91-96196 86917, +91-84509 80333

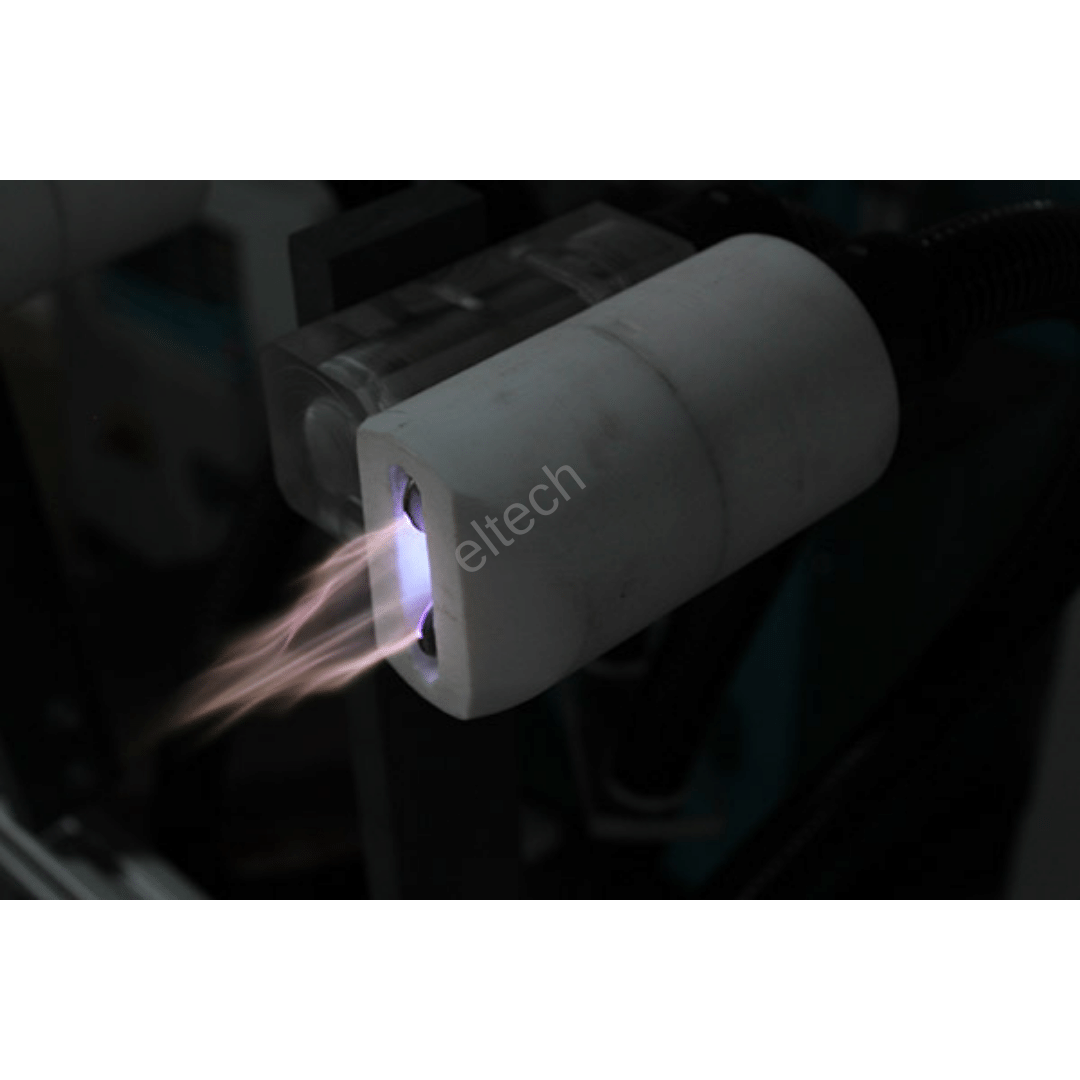

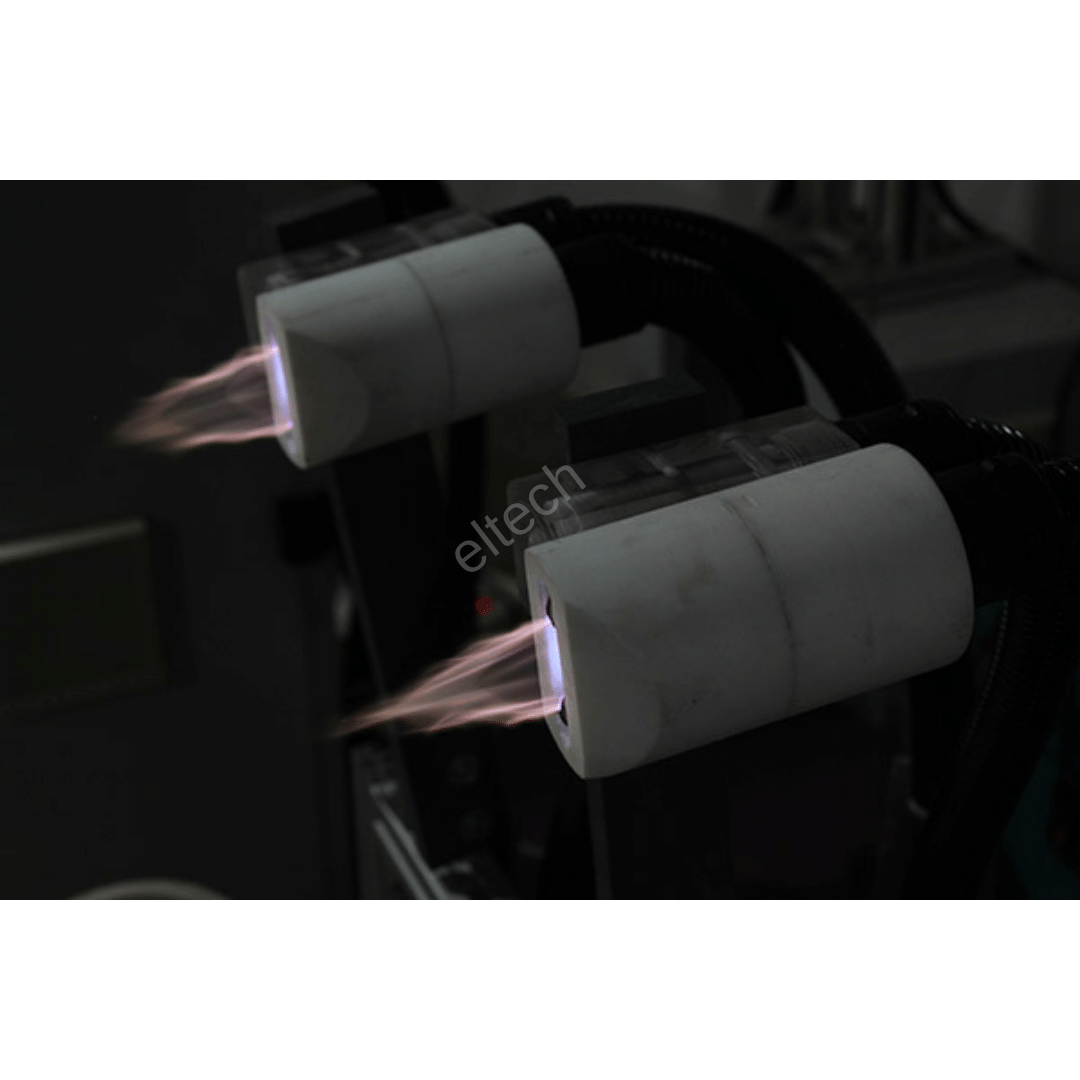

Plasma arc treatment is a type of surface modification process used to improve the adhesion properties of materials. It is a non-thermal, low-pressure plasma treatment that uses an electric arc to generate a high-energy plasma stream.

During plasma arc treatment, a gas is ionized and excited by the electric arc, creating a high-energy plasma stream that is directed at the surface of the material to be treated. This plasma stream bombards the surface with ions and reactive species, removing contaminants and functionalizing the surface with new chemical groups.

Plasma arc treatment can be used to modify a wide range of materials, including plastics, metals, ceramics, and composites. It is particularly effective at improving the adhesion of materials that are difficult to bond, such as polypropylene, polyethylene, and fluoropolymers.

Plasma arc treatment can be used in a variety of applications, including surface cleaning, surface activation, surface functionalization, and surface coating. It is commonly used in the manufacturing of medical devices, automotive components, electronic components, and other products that require strong adhesion properties.

One of the benefits of plasma arc treatment is that it is a dry, environmentally friendly process that does not require the use of solvents or other chemicals. It is also a fast and efficient process that can be easily automated for high-volume production.

Eltech's Plasma Arc treatment system is perfect solution to adhesion problems on injection, blow moulded or extruded parts of PE, PP, PET, nylon, vinyl, polystyrene, polycarbonate, PVC, fluorocarbons and all other types of thermoformed and thermoset plastics. plastic surface treatment is achived with Plasma Arc treatment.

Plasma Arc can be used in a very flexible way, since a counter electrode is not needed. Atmospheric Plasma Treatment can be used in a very flexible way, since a counter electrode is not needed. The discharge is ignited between a pair of electrodes inside the treatment tool and gets directed towards the substrate with a minor laminar air flow.

3D Corona treatment system readily solve surface adhesion problems for a wide variety of products and applications: