Atmospheric Plasma Ion Treatment

Eltech's Plasma ION provides an economical solution for cleaning & activation of component surfaces before further processing. Plasma surface treatment improves wettability and adhesion of ink, glues and coatings on many different surfaces.

Eltech's Plasma treater etches, cleans, activates, sterilizes & functionalizes a wide variety of difficult to treat conductive and non-conductive material surfaces.

Plasma offered by Eltech permits east surface treatment of a large variety of parts.

Its concept based on three principle oh high voltage discharge in a high frequency area.

Compressed air presses the discharge outside the nozzle head. The entire system is easily integrated into new or existing production lines.

The system consist of a plasma generator with nozzle assembly.

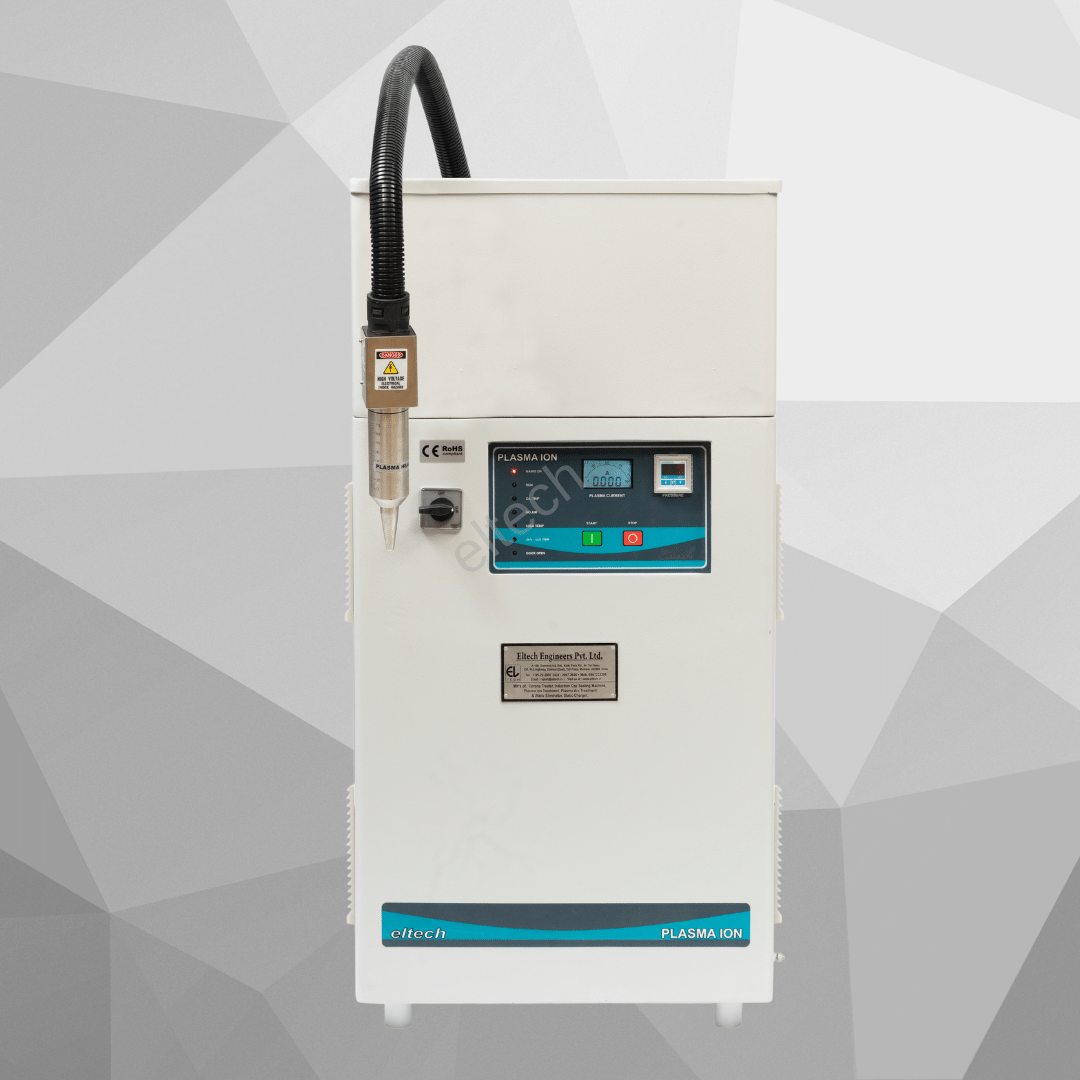

Single Head Plasma Ion Treatment

Single Head Plasma Ion Treatment

(iplasma-AC-1000)

Single Head Plasma Ion Treatment

(iplasma-OC-1000)

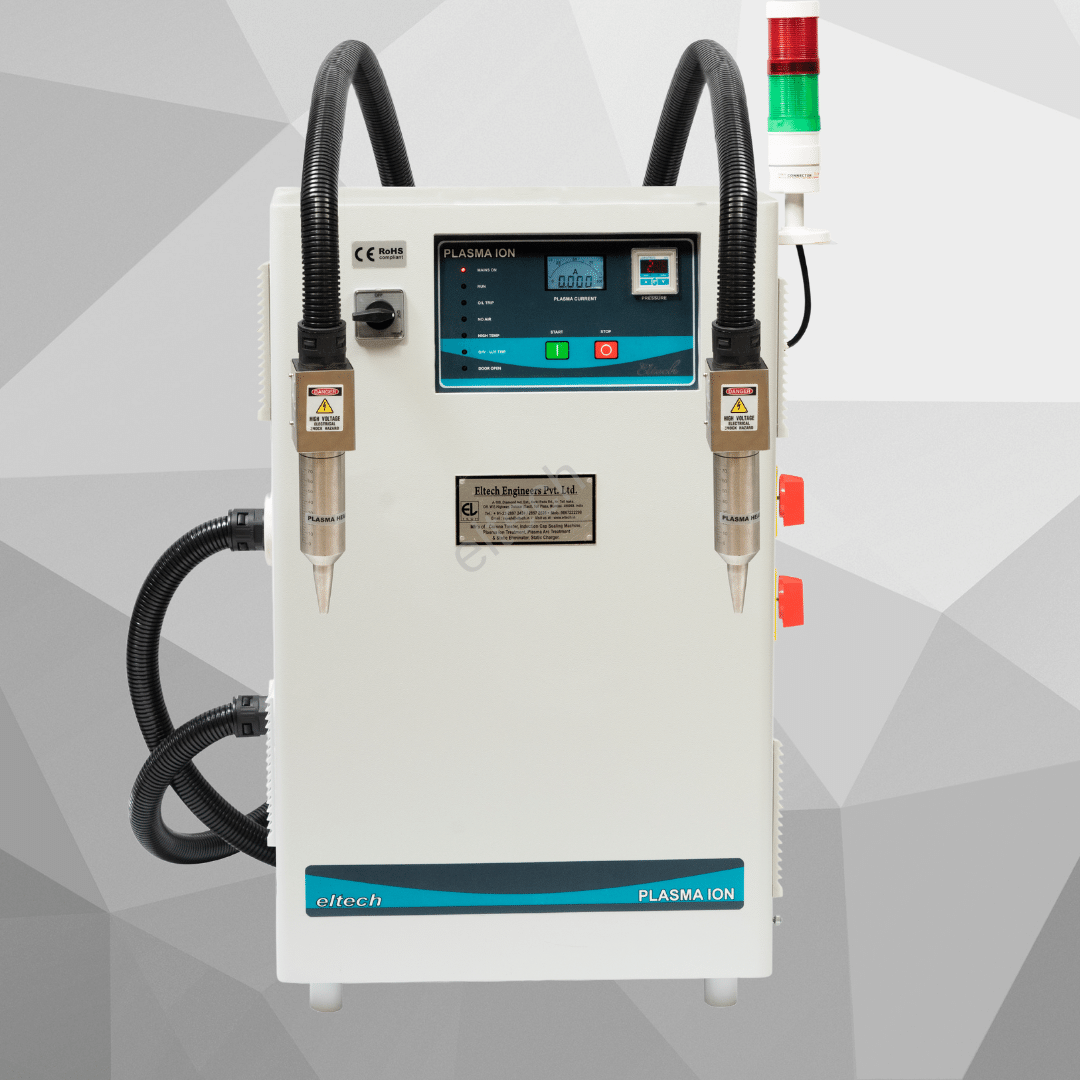

Dual Head Plasma Ion Treatment

Dual Head Plasma Ion Treatment

(iplasma-AC-2000)

Dual Head Plasma Ion Treatment

(iplasma-OC-2000)

Benefits of Plasma Treatment over Acid

- Improves the physical properties of etched material.

- Unlike Acid, Plasma is also an excellent cleaner & removes all the unwanted organic residues from the metal surfaces.

- Although plasma improves chemical & physical properites of the metal but it does not change any property.

- By-products formed during plasma etching are volatile.

- Plasma etching is less risky than acid.

- Potential free discharge which can treat both conductive, non-conductive as well as semi-conductive surfaces.

- Easy operation by simple button ON/OFF and Start/Stop.

- Ultra high frequency using latest IGBT technology.

- Air-Cooled HV transformer for better efficiency & long life with high-speed cooling.

- Fans that can be used for long hours.

- Compact construction with maximum operator safety.

- Potential free contact interlock for integrating with PLC for Start/Stop command.

- Fire-resistant conduits & other plastic components.

- Constant power for high & uniform surface treatment.

- Long Lasting, Uniform, High surface treatment levels.

- Auto / Manual Operation Switch.

- Ideal for high-speed lines.

- Reliable Industrial Design.

- Forced cool converter for longer life

- Easy to maintain

- Easy to install

- Cost efficient treatment process

- HV transformer is able to used for long hours and continous work

- Maximum operator safety

- Soft start

- Compact simple construction

- Overload Trip

- Thermal trip for heatsink

- MCB protection

- Under voltage / Over voltage

- No Air

- Door open

- Under Current / Over Current

- Audio / visual alarm