- info@eltech.in

- +91-96196 86917, +91-84509 80333

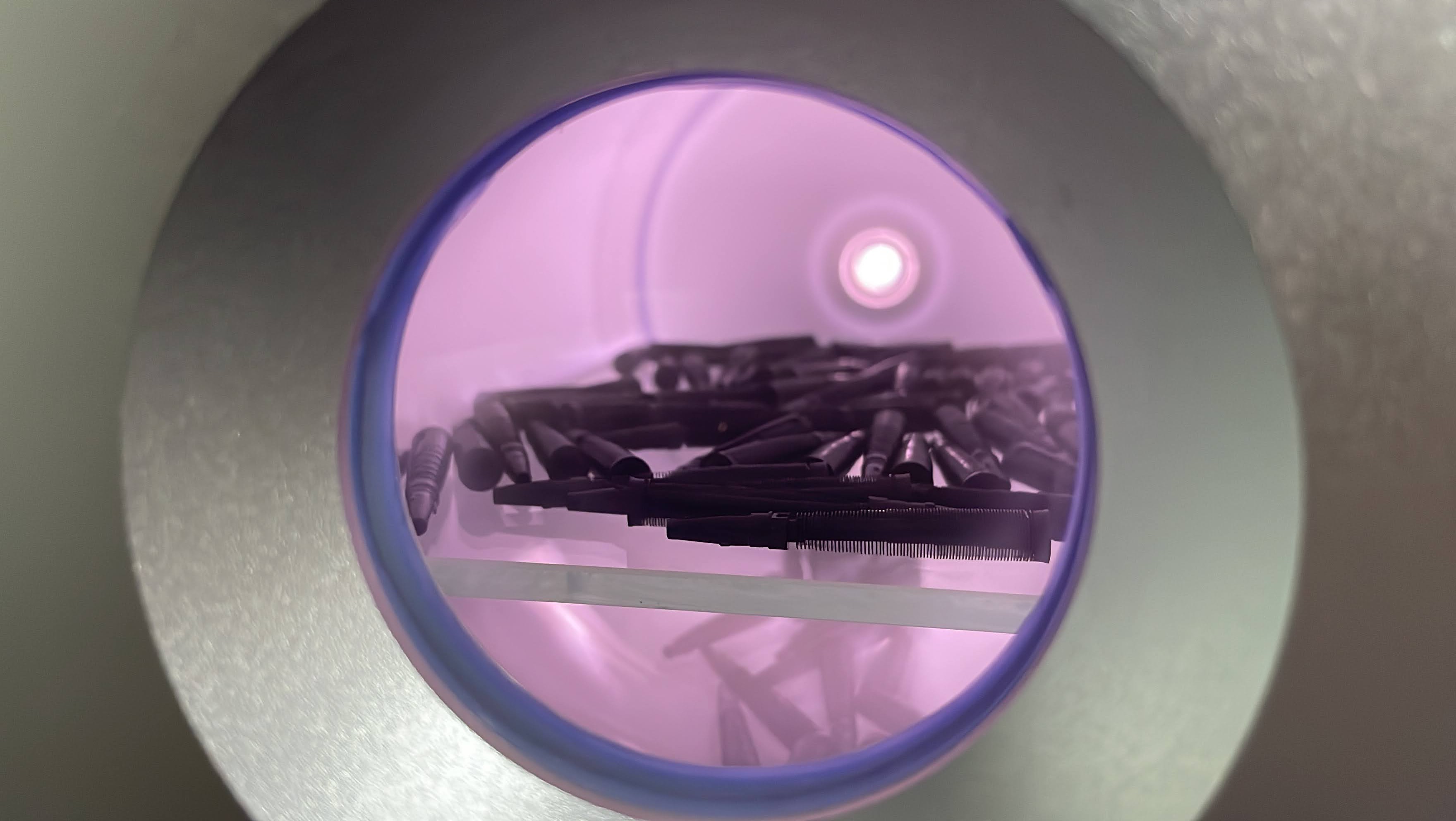

Eltech's Laboratory Vaccum Plasma unit is portable, small enough to fit onto a bench and is a cost effective solution to the problem of improving surface wettability. The lab vacuum plasma unit is very simple to install and can be operational within minutes.It comes equipped with its own vacuum pump. Featuring operator friendly & easy to learn and use. The see-through door enables you to see your parts being treated in the large chamber. All of the key parameters are adjustable (i.e. treatment power, time & vacuum level) allowing you to achieve total process control.

Eltech Engineers supplies plasma solutions to improve the surface energy of plastic and rubber components to ensure good adhesion of printing inks, paints, adhesives, coatings etc. and for the surface cleaning of plastic, rubber and metal parts. Plasma surface modification equipment is widely used throughout a diverse range of industries and onto an ever increasing range of substrates. Our growing list of customers includes many in the following industries: medical, automotive component, electronics, cable, pipe and many more. Through our many years of experience and continuous product development we have become one of the leading suppliers of Plasma Surface Modification equipment, Eltech Engineers is here to help you find the most appropriate surface modification technology and equipment to solve your problem.

Vacuum Plasma provides innovative surface modification technology and offers effective solutions to adhesion and wetting problems in many industries. Component preparation using plasma treatment is an important step prior to printing, bonding, painting, varnishing and coating processes.Plasma surface modification provides an economical solution for the cleaning and activation of part surfaces before further processing.

To obtain good adhesion to low surface energy materials i.e. low or non-polar materials like PP, PE, HDPE etc. we need to modify the surface i.e. increase its polarity. Placing your components in the highly active environment that exists inside a plasma chamber is the ideal method to increase the material's polarity. The free radicals and other particles that exist in the highly active plasma discharge can attach to the material surface resulting in the formation of additional polar groups on the material surface, these have a strong chemical attraction to inks, paint, coatings, adhesives etc. leading to significantly enhanced surface energy and therefore adhesion.